Ready to revolutionize your data journey with Infoveave?

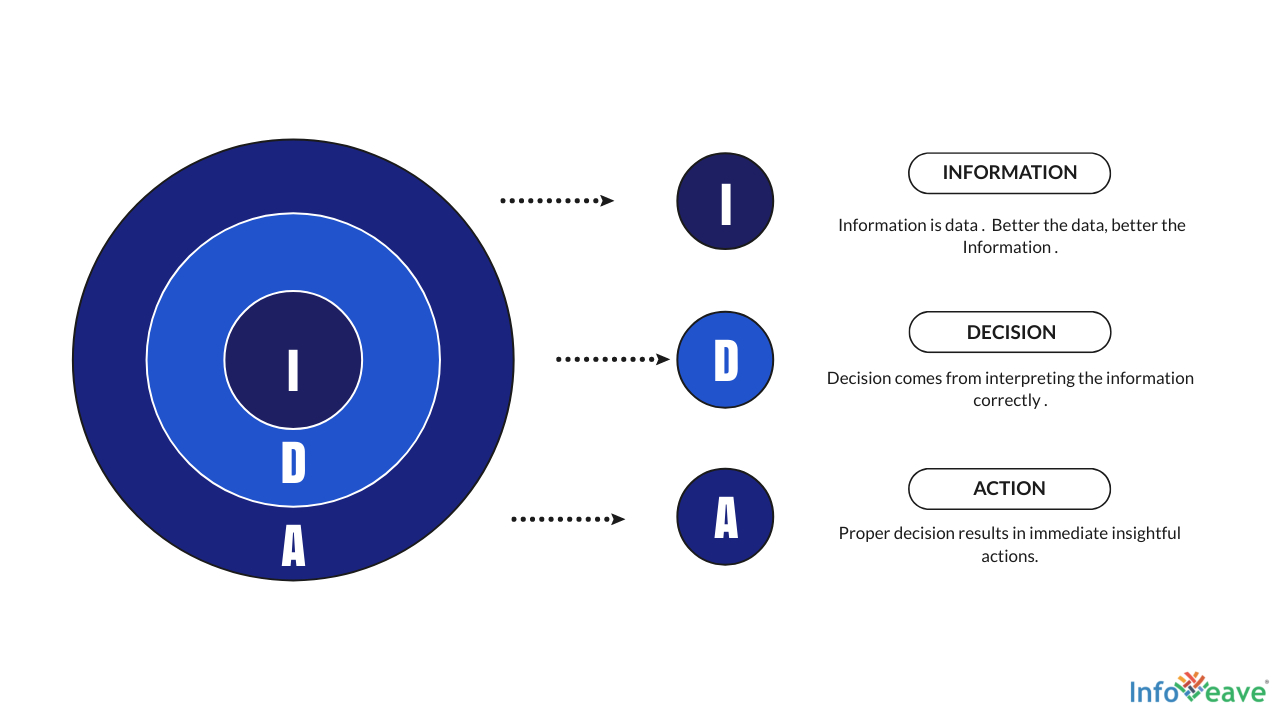

IDA strategy on OEE

OEE has become an important driver for businesses in achieving manufacturing intelligence. Industry 4.0 technologies enable businesses to gain insights into their production processes. Every manufacturer’s roadmap to maximizing OEE efficiency is going to vary based on their business requirements. Improving the OEE may involve making a few changes to the existing framework. On the same note, it can also involve adopting new strategies altogether.

The roadmap to improving the OEE efficiency involves a few necessary steps. They are- collecting relevant data, making effective decisions, and implementing effective strategies. A popular methodology for optimizing OEE is the IDA approach.

IDA stands for information, decision, and action and is an effective tool for businesses to reach their manufacturing goals. The information enables informed decision-making, with action transforming the decisions into concrete results. Similar to the OEE formula, you can multiply the IDA components to get the result.

I (Information) x D (Decision) x A (Action) = R(Results)

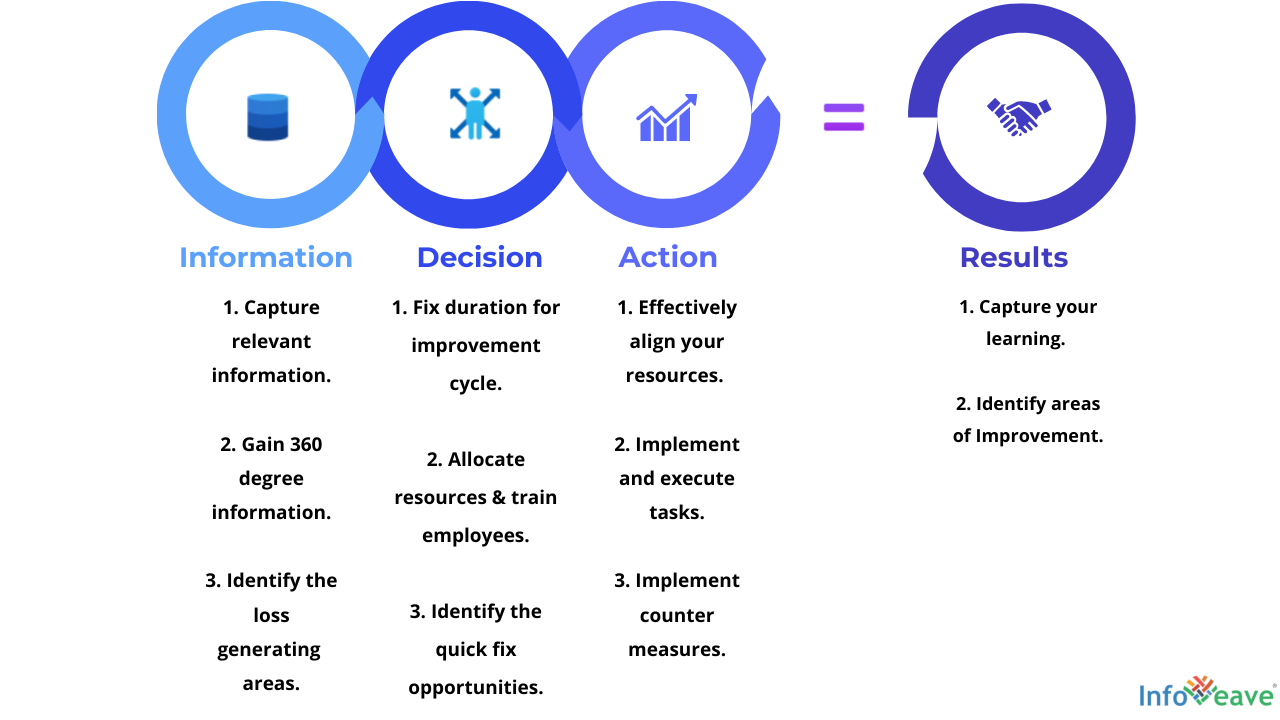

Information

Accurate information is the foundation for maximizing your OEE efficiency. Having relevant and up-to-date information is fundamental to improving your day-to-day manufacturing operations. This becomes extremely critical to not only identifying constraints but also making informed decisions. Collecting data with OEE intelligence capabilities is the first step to identifying manufacturing constraints. Presenting the data via an OEE dashboard measure APQ measurements in real time. Businesses can keep a bird’s eye view of the problems, what caused them, and the time it took in resolving each issue.

Organizations can leverage the information to compare losses and identify the areas that are generating the highest losses. In this way, manufacturers can prioritize OEE improvement strategies for production lines that require immediate attention.

Decision

The second step in the IDA process is decision-making. After collecting relevant information and gaining insights, businesses must strategize how to improve the OEE. Before making decisions, manufacturers need to consider the following factors.

- What changes are to be made?

- How much will it take to implement the changes?

- Who will carry out the changes?

Manufacturers must decide on the duration of improvement cycles. The period should be long to execute the changes successfully. On the same note, it should be short enough not to lose focus along the way. Not every loss in your manufacturing unit will be an equal contributor. Identify the factors that contribute highest losses and shift your attention toward them. It is also important to focus on improving losses which are more likely to produce the highest results.

While selecting losses to work upon, you should keep the following in mind.

- That your team has the required expertise for improvements.

- The loss requires minimal to no external intervention.

- Actions can be implemented quickly.

Actions

The final stage of the IDA method is taking action. It is the process of transforming plans and strategies into tangible outcomes. When you carry out successful actions based on your decisions, you ultimately maximize the OEE efficiency.

Before taking action based on the collected data, manufacturers must ensure all their resources are aligned together. Some important measures include:

- Educate your team members to ensure everyone is on the same page.

- Include all the tasks in the improvement cycle.

- Schedule the tasks properly to avoid overlapping.

- Make sure to buy any replacement parts if needed.

- Stay focused throughout the different stages of your project.

You must invest enough time in each course of action to properly execute the measures for improvement. An OEE dashboard provides a comprehensive view of the areas that require the most attention. You must allocate proper time and attention to these tasks and address them in detail. Once businesses take action, they need to re-examine the steps and identify.

- What actions were successfully carried out.

- Areas for further improvement.

- If and why strategies should be changed in future.

Results The final results depend on how well you manage the three IDA processes. If you get desirable results, that means every input was implemented

properly. If not, identify the areas of weak spots in your IDA journey for improvement. You may retrospect on some steps, such as:

- Whether the data was completely accurate?

- Did you make the right decisions?

- Did you brief each team member properly?

- Was there complete focus throughout the project?

Maximizing OEE efficiency is not a simple one-day procedure. It is a journey of continuous assessment with accurate, up-to-date information to align resources better and improve worker collaboration.

With Infoveave’s OEE dashboard, now share performance in real time with the concerned stakeholders. Our low-code no-code digital solution helps you identify recurring problems and their causes. Now unlock consistent production value by tracking plant operations on the go. And what’s more? You can do all this and more at competitive rates. Partner with Infoveave today and pave the way for a more efficient manufacturing process.